retour

Neopolen® (EPP) is a polypropylene foam consisting essentially of expanded foam particles, the majority of which are closed-cell.

The many properties of Neopolen® make it a versatile engineering material suitable for a wide range of applications in the automotive, packaging and industry. Its main characteristics are excellent energy absorption, low weight and high thermal stability.

Neopolen® (EPP) is a polypropylene foam made from expanded, predominantly closed-cell foam particles. Usually supplied in loose foam particles, it is processed into a wide variety of foam parts in foaming machines. The standard product range covers a molded density between 20 and 100 g/l.

The advantages of Neopolen® material include :

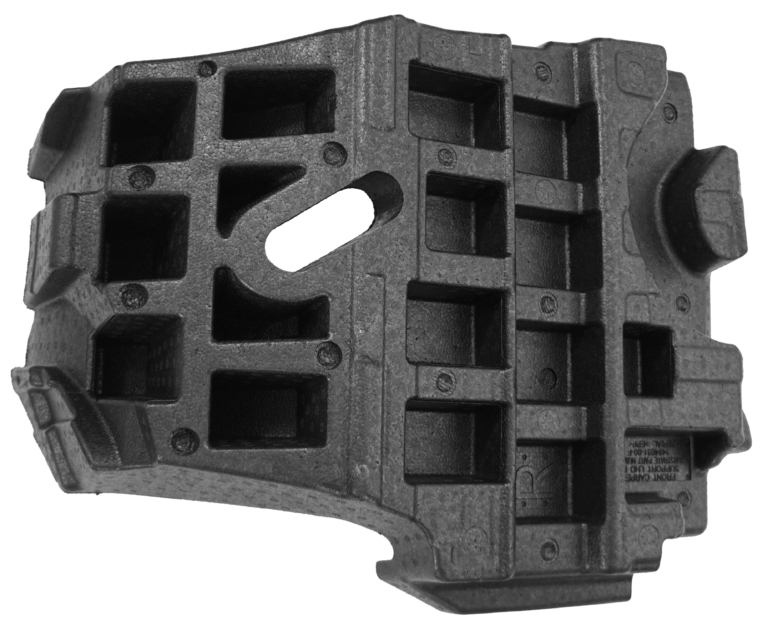

Due to its mechanical properties, Neopolen® is particularly suitable for components subject to impact stress. The low weight, high energy absorption and good deformation performance of Neopolen®, even after repeated impact load, are outstanding qualities for components in automotive construction.

Neopolen® also has negligible water absorption, can be relied upon to function reliably over a wide range of temperature, and is thus predestined for internal and external applications in automotive construction.

As an engineering material with many different properties, Neopolen® performs several functions at once. The molded parts are equally suitable for packaging, for casings, as impact protection and as heat and sound insulation, e. g. for electronic devices and heating equipment.

Therefore, new design possibilities are opened up in the field of technical and electronic devices. Components such as ventilator fans or electronic components that were previously fastened in metal holding devices can be reliably anchored by closefitting insertion into the viscoelastic assembly frame of Neopolen®. This saves time and weight while simultaneously assuring a high level of transportation safety.

Compared to other foam materials, Neopolen® is especially suitable for reusable packaging and reusable transport containers. The high resilience after static and dynamic stressing and the good chemical resistance, as well as the excellent cushioning performance at extremely low weight, make Neopolen® ideal for these applications.

Examples are in-plant transport containers for automobile mirrors, brake calipers or steering gears. Depending on the level of stress, 100 and more transport cycles are regularly achieved. In this way Neopolen® helps to economize on packaging materials and lowers costs.

In the leisure and toy sectors, products made of Neopolen® benefit from the combination of light weight and durability.

In addition to these properties, this special foam lends itself quite well to the realm of sports, thanks to its high resilience and elasticity.

The Neopolen® standard brands cover a wide density range and are thus suited for a variety of applications. The progressive product range offers lightweight products of a molded part density of 20 kg/m³ (P 8220 K), e.g. for packaging applications, to heavy brands with up to 100 kg/m³ for stable construction parts.

Bright red, deep blue, light blue, rich green or shiny yellow: these are the colors of the Neopolen® color range. All color brands are produced with high-grade pigments and allow usage in the most different applications.

The OEKO-TEX® 100 certified Neopolen® P 8015 K is the lightweight in the product range. With only 13-17 g/l, it is very suitable for stable packaging, but also as a filling for beanbag chairs, pillows and medical positioning aids.

The unique metallic gray color of Neopolen P 9335 MG makes it perfectly suitable for valuable applications in visible areas. With its further improved heat insulation (compared to standard products) this Neopolen® P type also provides advantages in technical applications.

Conductive Surfaces

During transportation, friction can cause electro-static charges to occur on the surface of the packaging. When this is discharged, sensitive electronic components in parts such as display instruments or navigation and electronic entertainment devices can be damaged. For the production of safe ESD packaging, Neopolen® P 9230 ESD offers an electrostatically effective brand which can be used to produce packaging systems with defined surface resistance. This electrically conductive effect is guaranteed for the full lifespan of the molded part and is even maintained in the case of changing climatic conditions (humidity, heat), which is a particular advantage for use in company-internal transport containers.

Improved Thermal Insulation

In the wide Neopolen® range, Neopolen® P 9335 MG (metallic grey) is characterized by even more improved thermal insulation properties compared to the standard products.

Looking for more detailed information? Please consult the technical & safety data sheets below.

Neopolen Technical Data Sheets

Neopolen Safety Data Sheets German Version

We are at your disposal to bring you the best possible solutions.