retour

As part of its CSR (Corporate Social Responsibility) approach, Knauf Industries is committed to offering sustainable packaging solutions in favor of the circular economy.

As a manufacturer of packaging and technical moulded parts, in plastics foams – expanded polystyrene EPS and expanded polypropylene EPP , we combine performance and growth to offer ever greater business expertise. In 30 years, we have developed our know-how and our mastery of the various technologies related not only to packaging but also to the manufacture of technical parts.

We regularly bring to market more sustainable product and service solutions that contribute to our customers’ success. This is how we ensure long-term success with our customers in a wide range of industries – agri-food industry, domestic appliances & HVAC, automotive and industries.

In partnership with our suppliers, we are working on new materials foams that meet the increasingly demanding expectations of our stakeholders. Our current projects include solutions using foams from renewable or recycled resources* and speciality foams with high levels of thermal resistance, mechanical strength or low VOC or CO2 content, for example.

Our mission is to provide our customers with solutions for the circular economy to ensure sustainable growth!

As part of its Corporate Social Responsibility (CSR) policy, Knauf Industries is committed to innovating for a more circular economy.

Knauf Industries has developed NEOPS®, a foam material made from raw materials derived from sustainable renewable resources1 and certified throughout the value chain by REDcert², a certification system for the use of renewable resources.

“For the manufacture of NEOPS® products or parts, the entire value chain is certified, from the resource used to the manufacturing process. The certification of each stage enables us to obtain a product certificate issued by REDcert²”.

NEOPS® is an alternative to expanded polystyrene (EPS) manufactured using the Mass Balance approach. This material innovation by Knauf Industries is the result of collaboration between ID lab, our innovation and development laband raw material producers.

NEOPS® is available with different performances (thermal, fire resistance, shock absorption and food contact). At the end of their life, NEOPS® products can be sorted and recycled through existing EPS channels.

This innovation reduces the use of fossil raw materials and cuts greenhouse gas (CO2) emissions by at least 30%2.

To date, 18 Knauf Industries sites are REDcert² certified: 16 in France and 2 in Spain.

The new mono-material suitable for food packaging made from up to 100% recycled post-consumer plastics. Formulated on a polypropylene PP base, it is intended for the manufacture of thermoformed or injected products and complete the KAP’ range of materials by offering a perfect sealing quality under protective atmosphere or under skin. It can be microwaved and pasteurised and is available in Kapseal®, Kapclear® and Kaplight®. In addition to its excellent sealing qualities, R’kap® is 100% recyclable in existing PP channels.

Knauf Industries favours solutions based on recyclable and recycled materials that can be integrated into sorting channels.

With its ID lab development and innovation center, KNAUF Industries is committed to innovating, co-developing and researching more responsible materials to offer its customers packaging solutions that contribute to the circular economy.

This material solution is also certified by TÜV in accordance with REDcert². REDcert² certification guarantees that producers of alternative raw materials have substituted virgin fossil resources with resources derived from the recycling of post-consumer plastic waste, and Knauf Industries is also part of this REDcert² certification process for the manufacture and marketing of its CELOOPS® products.

In the case of CELOOPS®, the resource used comes from post-consumer recycled plastic waste. The entire value chain is certified, from the resource used to the manufacturing processes. Certification of each stage enables us to obtain a product certificate issued by REDcert².

“A material of choice for packaging solutions and technical parts.”

In addition to being made from up to 100% raw materials derived from the recycling of post-consumer plastic waste, CELOOPS® is 100% recyclable at collection points, as well as in the Knauf Circular® loop, the KNAUF group’s service for collecting EPS waste and guaranteeing its recycling into new products.

The Mass Balance approach is an internationally recognised scientific approach for ensuring the traceability of material flows in value chains. It is recognised by the Ellen MacArthur Foundation as a solution in favour of the circular economy and has been used for over 20 years in many industrial sectors: energy, food, packaging, paper, wood, textiles, etc.

The Mass Balance approach consists of incorporating:

The range of EPS solutions containing recycled polystyrene!

This alternative to expanded polystyrene (EPS) is manufactured by mechanically recycling pre-consumer and post-consumer PS or EPS waste.

For packaging, the use of materials containing post-consumer waste entitles you to the eco-contribution premium, subject to the eligibility conditions of the eco-organisations, please contact us.

These materials provide a solution in favour of the circular economy because they reduce the use of fossil raw materials. Products made from RELOOPS® should be disposed of in the recycling bin, depending on their location, and can be recycled through existing EPS and Knauf Circular® channels, that collects, recycles and recovers your EPS waste into new products.

Example of MATERIAL SAVING with RELOOPS®

For a water heater manufactured at a rate of 100,000 units per year, the use of RELOOPS® protective padding with 35% recycled content saves of 35 tonnes per year of raw material instead from fossil feedstock.

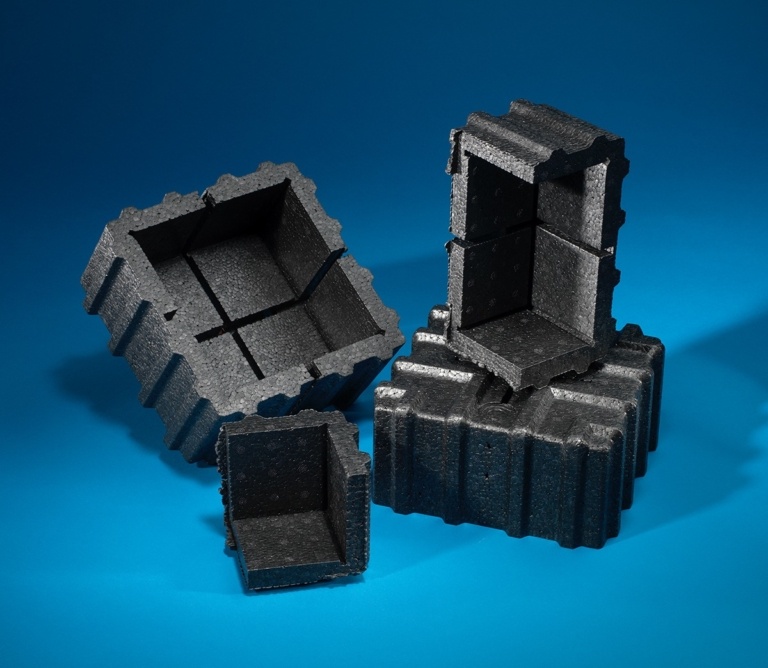

The range of PPE solutions containing at least 25% recycled polypropylene!

This alternative to expanded polypropylene (EPP) is made from post-consumer recycled EPP waste.

“RELOOPP® is suitable for industrial, HVAC, automotive and food processing applications. It is used to manufacture reusable packaging”.

These materials contribute to the circular economy by reducing the need to use fossil raw materials. RELOOPP® products can be recycled in EPP industrial processes.

Knauf Industries has initiated a Corporate Social Responsibility (CSR) approach since 2019.

Working with our suppliers and customers, we are committed to offering solutions that promote the circular economy. Our eco-design policy applies to every project with clear rules:

– involve all the internal and external players concerned by the product from the start of the project;

– Reduce the quantity of materials, by weight and volume;

– consider the re-use or re-employment of products right from the design stage;

– enable better sorting and recycling of parts by favouring the use of single materials;

– incorporating recycled materials from the sorting of industrial or household waste;

– incorporating more materials from renewable resources or recycled waste.

We are at your disposal to bring you the best possible solutions.