retour

ID Lab, our innovation and development lab, to innovate and co-develop your products.

Our vision at Knauf Industries is to be recognised as an innovative partner by our customers through the value we bring to their projects. To achieve this, we have created an innovation and development laboratory to disseminate an innovative mindset throughout the company.

At ID lab, we are constantly developing tools and methodologies to maintain the high level of excellence of our teams, to anticipate and respond to any potential for innovation in the countries and markets where Knauf Industries is present, and also to develop opportunities in new markets. We promote creative, customer-focused tools and ensure cross-functional sharing of information and innovation, regardless of the country, market or current processes: cellular foams, plastic injection, thermoforming, extrusion and contract cutting.

Our experts and engineers are close to our customers and are specialised by market, by material or by technology.

We deploy our skills and equipment to generate value-added solutions and identify new growth segments, business models and technologies.

A first Lab specialised in cellular foams (EPS, EPP, etc.), and speciality materials is based in France, in Ungersheim (68) to provide essential functions such as design, prototyping and testing.

A second Lab exists in La Bernerie-en-Retz (44), specialising in thermoforming and injection.

The objective is to combine the agility of a local structure with the strength of an international group, with all the Labs being connected and challenging their ideas and concepts.

ID Lab is the collective intelligence of a cosmopolitan team!

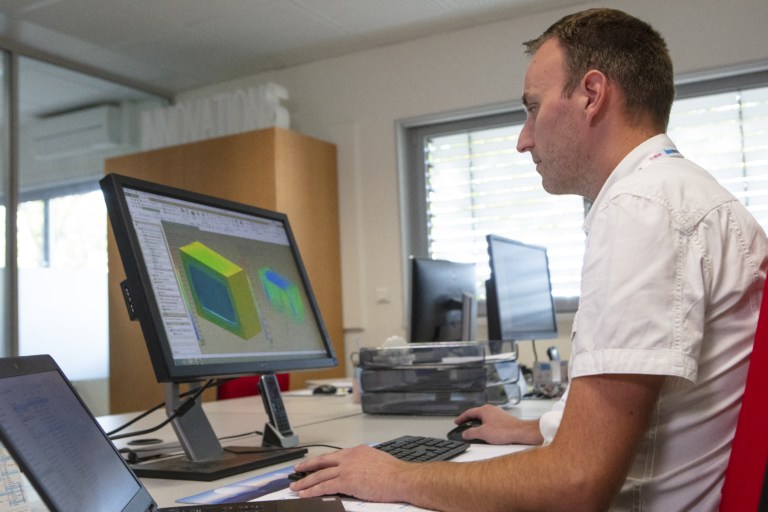

Thanks to digital technologies, we reduce development time by optimising our solutions with digital simulation to anticipate product performance before the prototyping phase.

Our strategic motivation: to develop the innovative spirit of our teams, to innovate in order to bring added value to our customers and to be recognised as an innovative company by the market!

We use 3D scanning technologies to analyse products and perform accurate and fast dimensional checks !

We optimise the amount of parts in the packaging with innovative design software.

We use augmented reality and realistic renderings to present our solutions to best match the reality of our customers’ environment.

In addition, our new surface treatment technology allows us to produce foam plastic looking parts, enabling our customers to target new markets or add value to their traditional markets.

Our innovation and development laboratory ID Lab has been equipped with a 3D scanner arm for scanning a physical part or a package from a scanned part.

With it, we do reverse engineering to provide a 3D file and create the most suitable packaging for our customers’ needs. The added value with this tool is the reduction of the “Time to Market“, product innovation and organisational and human efficiency.

We are at your disposal to bring you the best possible solutions.