retour

While expanded polystyrene (EPS) is a well-known material in the furniture industry, expanded polypropylene (EPP) is an innovative solution that is gaining more and more popularity in furniture component manufacturing. This light-weight and at the same time extremely durable foam material began to be used as a structural element in the construction of furniture. Furniture manufacturers choose polypropylene foam as an alternative to wood, plywood and in some case event to metal components. The material is successfully applied in both: indoor and outdoor as well as garden furniture production.

The parts from expanded polypropylene can easily constitute structural parts of sofas, armchairs, seats, and other furniture. The material is made up of 95% air hence EPP parts for furniture are 10 times lighter than wood and 40 times lighter than the ones made of aluminum. This means that furniture made using this material does not weigh much and is ergonomic which is crucial for end-users. One more important property of the material which is valued by the industry is the so-called “shape memory” meaning that EPP comes back to its original shape after the stress applied to it ceases. Thanks to that the furniture with EPP parts is comfortable and durable at the same time.

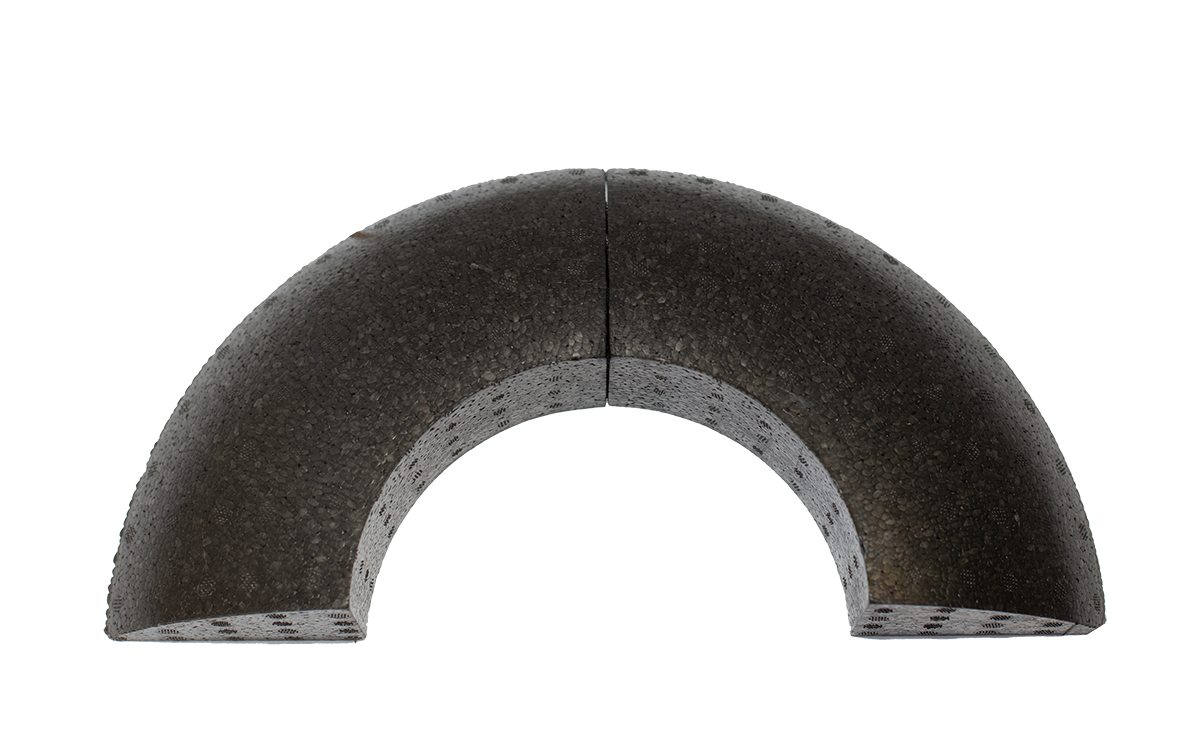

Expanded polypropylene allows for extraordinary freedom in designing forms and shapes that are unattainable in metal bending or in wood processing technologies. In particular all rounded shapes that give the furniture pieces a unique look are easily attained with the foam molding technology used for EPP component manufacturing. That is one of the reasons why innovative producers from the industry incorporate expanded polypropylene in their solutions for furniture. At Knauf Industries, we work closely with the design departments of furniture companies to support them in the replacement of traditional technologies with EPP. We design and manufacture reliable components for manufacturers of upholstered furniture who want to streamline their production process.

Furniture components made from EPP offer many advantages from the production process point of view. The EPP molding process applied in the part production at Knauf facilities guarantees the part accuracy and repeated quality which has an outstanding advantage over wood processing technology. The lightweight EPP parts can be easily assembled during the furniture production process. Moreover, one part can be designed to fit many various models based on the modularity concept which facilitates logistics and management of components in the client’s warehouse. Molding of components helps to reduce the number of operations in the assembly process. They also can be easily attached to one another either with help of regular screws or without them, if designed so. On the top of it, EPP foam can be used to create complex components with overmolded plastic or metal inserts.

The use of EPP not only does simplify the assembly process but also makes it more environment friendly. Polypropylene foam is a mono-material which is 100% recyclable as it is composed only of polypropylene granules filled with air. What’s more, there are varieties manufactured with recycled polypropylene, the so-called rEPP which offers an even more sustainable alternative to other traditional materials applied in the furniture industry. With rEPP our clients can decrease their CO2 footprint which constitutes a relevant part of their CSR strategies.

At Knauf Industries we support our clients all the way through the solution implementation. Our designers and product engineers can participate in the design of the customized EPP parts. In the beginning of each project, we carry out a feasibility study to define the most optimal solution from the process point of view. In addition to the component production process, we coordinate the development of the tooling necessary for foam molding of the parts. Therefore, the implementation of the innovative EPP solutions into our client’s production processes runs smoothly.