retour

Our expertise serving your products.

In 1949, the scientist Dr. Fritz Stastny, a chemist at BASF, discovered expanded polystyrene (EPS). When this raw material, in bead form, is combined with steam, it swells to up to 40 times its original size.

It can subsequently be reworked in moulds. Therefore, EPS is composed mostly of air.

98% air to be precise. For a long time, EPS was known in Europe under different names, such as polystyrene or “Styropor” among others.

Expandable polystyrene, our raw material, is manufactured in part by Knauf in Belgium. It is obtained by polymerising styrene and an expansion agent: pentane. In our factories, it undergoes pre-expansion, a decisive phase in the moulding process. Under the effect of steam, the expanded beads then grow by 50 times their original volume and develop a closed-cell structure made up of 98% air.

Equipped with over 240 presses, distributed throughout 40 production facilities, we deploy our closed-cell moulding expertise for the manufacture of items made of EPS (max.: 2000 x 1400cm, densities 18g/l – 60g/l)

Besides being customisable, our tools are “mobile” within our facilities. Their adaptability to a large number of machines makes it possible to envisage rapid transfer of production.

The diversity of our equipment (vacuum equipment, transfer and film complexing) allows us to adapt our production according to the complexity of your products. Complexing helps enhance the mechanical behaviour of the closed-cell foam object, by increasing its rigidity and making it more watertight.

Block moulding is used to manufacture parallelepipedal parts.

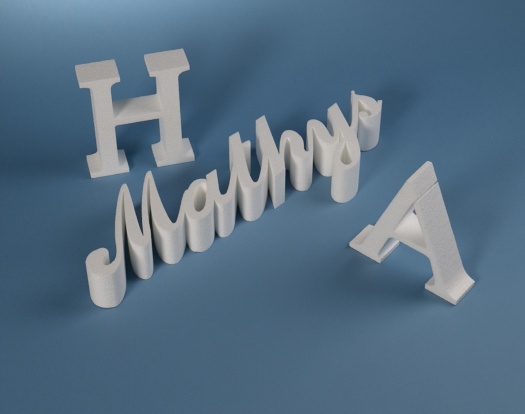

These “blocks” are then machined in our cutting workshops to make protective pads, decorative products or even prototypes.

EPS is one of Knauf Industries’ preferred materials!

Cutting is obtained by heating a steel wire which passes, at a regular speed, in a block of expanded material, previously manufactured from a block mould.

These cutting lines enable us to produce products with geometries of varying complexity.

Cutting allows for great creativity in item design and production. This process has many applications, which are suited equally well to small and large production runs.

Yes, EPS products are recyclable:

– Either by shredding and reintegrating into new technical parts or industrial packaging.

– Or by compacting to make raw material for the manufacture of plastic parts.

As the law on the circular economy was voted on 21 January 2020 by the French National Assembly, the Knauf Group is offering its customers and partners the Knauf Circular®* service to give a new life to EPS offcuts, packaging and wedges.

We are at your disposal to bring you the best possible solutions.