retour

EPP is a 100% recyclable material which meets your every need!

Expanded polypropylene (EPP) is a completely different base material to expanded polystyrene. It contains no swelling agent and is delivered to us pre-expanded. Initially used in industry as an insulating and cushioning material, Expanded polypropylene (EPP) is appreciated for its light weight, its optimal strength and high stability.

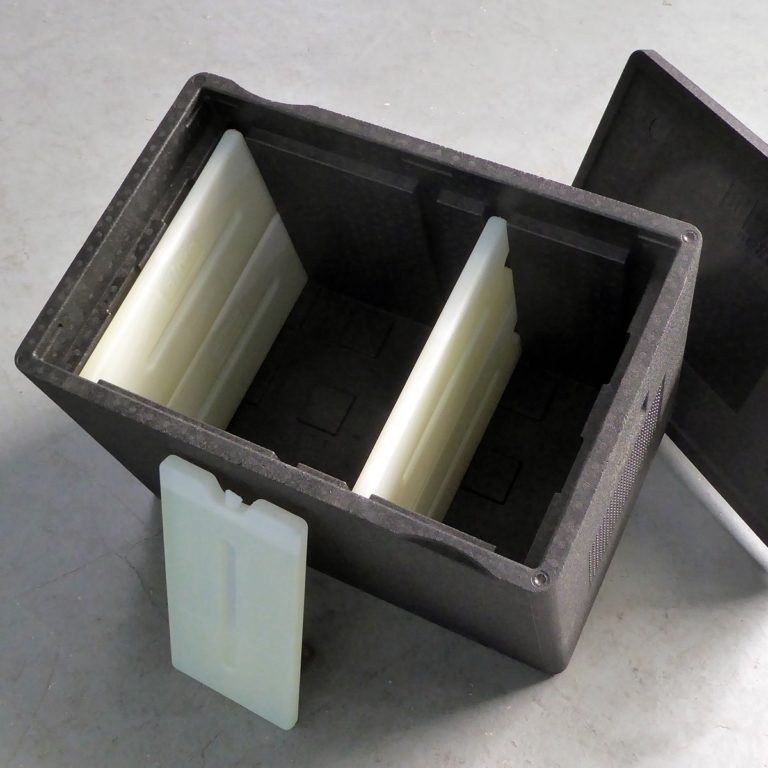

Expanded polypropylene (EPP) meets the most stringent requirements, particularly in terms of shock protection and thermal insulation and soundproofing.

Its unique mechanical characteristics make it very versatile to use:

– Automotive industry: shock absorbers, seats, boot compartments, mat cushions, etc.

– Agri-food: packaging, platters, etc.

– HVAC (heating, ventilation and air conditioning): boiler components, radiators, hot water tanks, air-conditioning units, etc.

Like most homogeneous thermoplastics, expanded polypropylene liquefies when heated and then hardens when cooled, in a completely reversible manner. It is therefore infinitely recyclable!

Find out more about our recycling actions.

You no longer need to choose between high performance, visual appeal and eco-design… and you can give free rein to your imagination!

Moulded products can be given new surface finishes (chemical or laser embossing, paint, etc.). Combining environmental concerns and retention of the initial qualities of EPP, they remain washable, reusable and 100% recyclable. Always with the same lightweight design and shock resistance.

EPP is one of the materials favoured by Knauf Industries!

Equipped with over 240 presses, distributed across 42 production facilities, we deploy our closed-cell moulding expertise for the manufacture of items made of EPP (max.: 2000 x 1400cm, densities 18g/l – 60g/l).

The diversity of our equipment (vacuum equipment, transfer) allows us to adapt our production according to the complexity of your products.

We strive to develop high-performance tools in brief time-frames and at advantageous costs.

Besides being customisable, these tools are “mobile” within our facilities. Their adaptability to a large number of machines makes it possible to envisage rapid transfer of production.

This moulding process guarantees very visually appealing items.

With our expertise in the transformation of expanded plastic resins, we now serve particularly demanding industrial fields. The diversity of our manufacturing processes allows us to choose the best for your products.

Cutting is obtained by heating a steel wire which passes, at a regular speed, in a block of expanded material, previously manufactured from a block mould.

We are equipped with multiple cutting machines:

– flat (parallelepipedal object)

– digital (2D object) and

– 3 axes (3D), for items with embossed designs, manufactured individually or in very small production runs

These cutting lines enable us to produce products with geometries of varying complexity.

Cutting allows for great creativity in item design and production. This process has many applications, which are suited equally well to small and large production runs.

We manufacture components, inserts and accessories for the automotive industry in collaboration with seat manufacturers. The excellent properties of the innovative expanded polypropylene (EPP) plastic make car seats both light and strong, but also very durable, to ensure the best possible safety for small passengers. EPP absorbs kinetic energy and does not deform even under repeated impacts.

We are at your disposal to bring you the best possible solutions.