retour

Since 2019, the year of signing our commitment to the United Nations Global Compact, we have been implementing targeted initiatives to strengthen our social policy, particularly in terms of diversity and inclusion, to engage with our stakeholders to promote more ethical business relationships throughout our supply chain, and to reduce the environmental impact of our activities as part of our environmental policy. Find all our commitments here.

In the face of unprecedented climate change, many countries have committed to achieving carbon neutrality by 2050. This is also the case for the Knauf Group, which is committed to decarbonizing its industry by reducing greenhouse gas emissions.

The Knauf Group has set identical objectives for all four divisions, including Knauf Industries:

To achieve these commitments and contribute to the fight against climate change, the Knauf Group and its divisions are actively mobilizing towards an ecological and sustainable transition, thus embodying their responsibility towards future generations.

Our corporate social responsibility approach has once again been recognized by EcoVadis. We are delighted to share with you our EcoVadis 2024 score!

EcoVadis is the global reference in CSR assessment. It is a platform that measures companies’ performance on crucial themes such as governance, social and human rights, environment, business ethics, and responsible purchasing. It objectively and comprehensively evaluates our CSR practices.

We are proud to share our new score of 71/100, which demonstrates our continued commitment to more responsible business practices. It reflects the thorough assessments of our policies, practices, and performance in corporate social responsibility (CSR).

Since 2016, we have been undergoing this rigorous evaluation. This approach provides us with the opportunity to progress while fostering transparent communication of our actions.

As part of Knauf Industries’ CSR policy, we aim to achieve the gold medal by 2025!

The EcoVadis assessment aims to:

This evaluation, in the form of an online questionnaire, involves providing supporting documents such as our CSR report, policies, and reporting, which will undergo careful scrutiny by EcoVadis experts.

This crucial step aims to assess the relevance of the information we provide and ensure its compliance with the rigorous criteria defined by the platform. EcoVadis has become a strategic tool for us and a means of structuring our business.

We would like to thank all those who have contributed to this success, our committed employees, and our strategic partners!

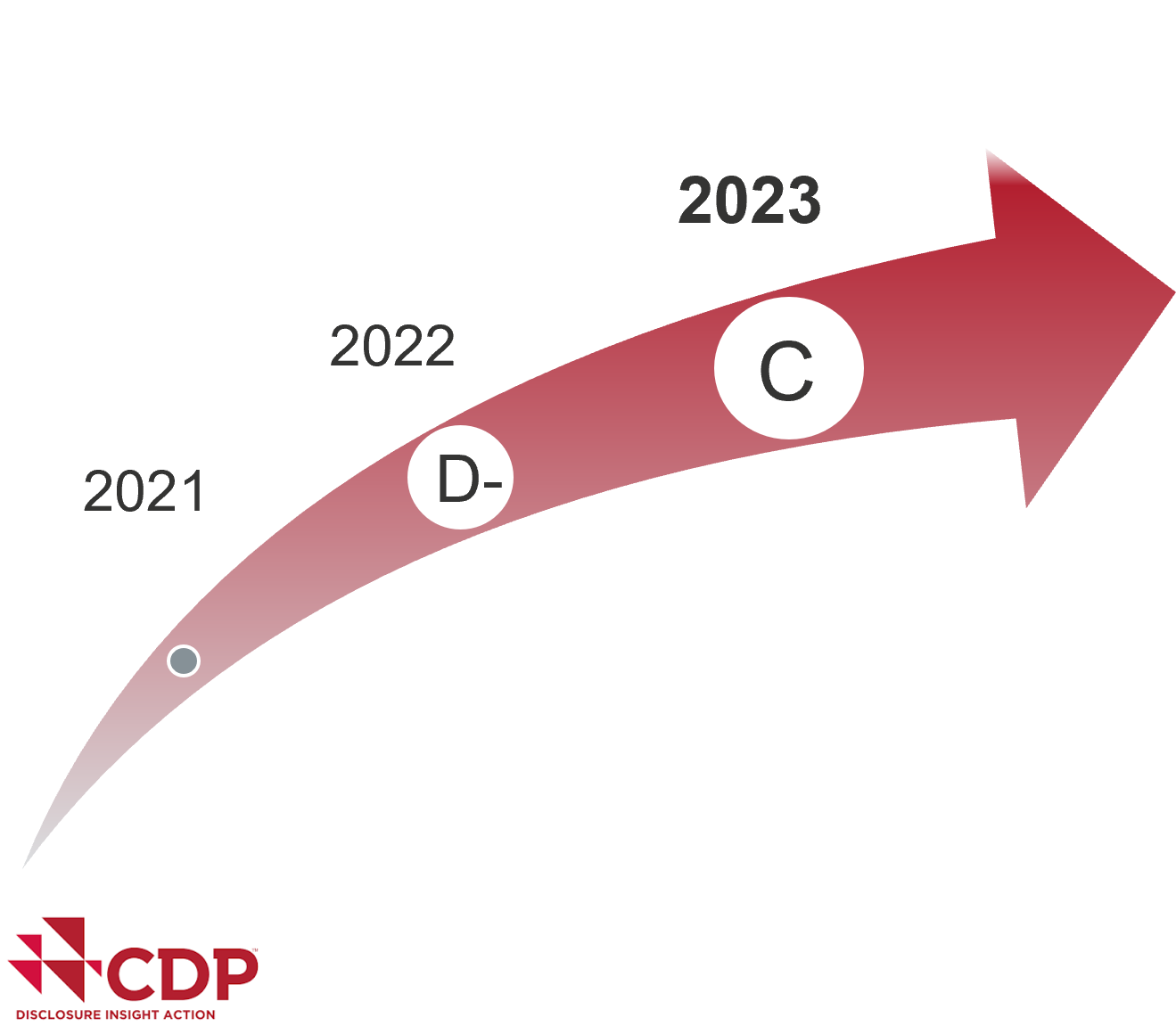

Every year, the Carbon Disclosure Project (CDP) evaluates companies based on their environmental performance and assigns scores ranging from A to D-, with A being the best score and D- being the worst.

We are also proud to announce that our CDP score has significantly improved, moving from a D- in 2021, D in 2022 to C in 2023 ✨.

CDP provides an essential analysis and reporting tool for sustainability-conscious companies. It allows them to voluntarily disclose their environmental practices, including their business strategy, governance, risks and opportunities, indicators, and commitment to stakeholders.

This rating brings credibility. CDP is an independent organization that measures companies’ environmental performance. It is recognized by investors, customers, NGOs, and governments as a global reference in environmental reporting.

Publishing our score demonstrates our commitment to transparency and our efforts in sustainability.

In addition to risk management, the rating assigned by CDP also offers significant innovation opportunities for companies. By assessing and rating companies’ environmental performances, CDP allows them to identify areas for improvement. These improvements can not only lead to better environmental performance but also significant impact reductions.

To find out more about our CDP rating, please follow this link and in the form, enter “Knauf Industries” in the “Organization name” section.

We are delighted to inform you that Knauf Industries will be exhibiting at Mostra Convegno Expocomfort (MCE) in Milan, Italy in March 2024.

This exhibition is a renowned event in the field of heating, air conditioning and ventilation.

You are cordially invited to visit our stand to find out more about our latest innovations, meet our team of experts, discuss the challenges facing the industry and how our products can meet your specific needs. Visit the Knauf Industries Appliances website.

Knauf Industries has recently published two white papers highlighting significant innovations in the fields of packaging, on reusable solutions. These in-depth documents demonstrate Knauf Industries’ efforts to inform its stakeholders about current trends, particularly in the industrial, transport and food sectors.

In 2017, Bulle d’air®, a Knauf Industries brand, embarked on the ambitious mission of creating a range of products focused on logistics and in particular handling and storage functions, in order to meet its customers’ needs more easily.

This has led to the creation of a comprehensive range, which focuses on lightweight handling, strength and durability. KOMEBAC® is a lightweight plastic container – the lightest on the market. The name KOMEBAC® refers to reverse logistics (come back), underlining the importance of reuse rather than simply recycling.

This has led to the creation of a comprehensive range, which focuses on lightweight handling, strength and durability. KOMEBAC® is a lightweight plastic container – the lightest on the market. The name KOMEBAC® refers to reverse logistics (come back), underlining the importance of reuse rather than simply recycling.

This white paper highlights the key features and benefits of KOMEBAC®, one of Knauf Industries’ solutions for the plastics circular economy. It also compares the different materials – cardboard, injected plastic and expanded polypropylene – to help customers choose the right solution for their packaging and transport needs.

“Our mission is to promote the use of reusable and returnable plastic packaging, leading to an overall reduction in plastic waste by advocating a fair regulatory framework for secondary packaging.”

Read the white paper here

The second Knauf Industries white paper, drawn up by the Knauf Agri-food team, focuses on the reuse of food packaging. Reuse contributes to the circular economy by extending the life of trays and boxes, reducing waste production and the use of fossil resources.

What is a reusable packaging?

“Packaging that has been designed, created and placed on the market in such a way that, during its life cycle, it can make several trips or rotations by being refilled or reused for a purpose identical to that for which it was designed”, according to article R543-43 of the French Environment Code.

Reuse is: “any operation by which substances, materials or products that have become waste are used again.“

Through this white paper, Knauf Industries promotes the reuse of packaging in the agri-food sector and provides insight for marketers who don’t know where to start. Knauf Industries Agri-food shares innovative strategies and initiatives put in place and highlights the benefits of reuse, underlining the crucial role it can play in creating a more circular supply chain.

Ask for the white paper here (in french only)

By publishing these white papers, Knauf Industries is demonstrating that continuous innovation is at the heart of its concerns. These initiatives serve to inspire others in the industry and pave the way for a more circular plastics economy and a more responsible use of our resources.

Contact us for more information about these white papers.

Knauf Industries unveils its new CSR Report 2023, – More than just words, actions – Continued No. 2!

Following on from its last two CSR reports, this new edition describes Knauf Industries as a whole, the actions taken and developments in 2022.

Knauf Industries is recognised worldwide in the fields of plastic packaging, polystyrene insulation and the manufacture of technical parts in expanded polystyrene (EPS) and expanded polypropylene (EPP). In response to current market trends, Knauf Industries stands out for its unrivalled expertise in the innovative use of these versatile materials.

This new Knauf Industries social responsibility report is in line with the United Nations Sustainable Development Goals (SDGs) and the 2030 Agenda.

By signing the United Nations Global Compact in 2019, Knauf Industries has committed to respecting the ten founding principles grouped under four fundamental themes: human rights, working conditions, the environment and the fight against corruption.

It reflects the company’s deep commitment to sustainability, as well as to ethics and transparency. You will find a comprehensive roadmap setting out the company’s progress and objectives for a more sustainable future.

Knauf Industries’ new CSR report covers a wide range of topics and highlights the company’s achievements over the past year, including:

Notable achievements include:

These achievements show that Knauf Industries is putting its commitment into practice: More than just words, actions!

To find out more about Knauf Industries’ CSR objectives and initiatives, we invite you to consult the full report in the Documentations tab.

📢 Our third Corporate Social Responsibility report – More than just words, actions – continued N°2 is finally available – in digital format only 📲 !

As part of its Corporate Social Responsibility (CSR) policy, Knauf Industries is committed to innovating for a more plastics circular economy. Knauf Industries now offers a wide range of single-material product solutions as alternatives to current petroleum-based materials, contributing to the circular economy of plastics: from packaging products to technical parts.

As a converter of cellular foams – expanded polystyrene (EPS) and expanded polypropylene (EPP) – and in response to the ever more demanding expectations of its customers, Knauf Industries embarked on a transformation towards the circular economy in 2020. “Our mission is to offer our customers solutions in favor of the circular economy, in order to guarantee sustainable growth!”

Knauf Industries innovates through materials, developing material solutions from renewable resources (like biomass) or recycled materials (derived from the recycling of post-consumer plastic waste), avoiding the use of fossil feedstocks as little as possible, in partnership with raw material suppliers.

These solutions fit in perfectly with the circular economy proposed by the Ellen MacArthur Foundation.

Our innovation and development center, ID lab Knauf Industries, develops material solutions incorporating up to 100% recycled materials, or derived from sustainable renewable resources.

These new materials are used in the manufacture of packaging and packaging solutions, as well as in the manufacture of technical or construction parts.

Knauf Industries therefore ensures that the resources used to manufacture these solutions do not compete with food resources (the use of organic waste, for example).

Knauf Industries undertakes to ensure that any material solution developed, or product manufactured has an existing recycling channel or one that is being set up in the short term.

Knauf Industries is committed to innovating, co-developing and researching less impactful materials to offer its customers packaging solutions that contribute to the circular economy of plastics.

This alternative to expanded polystyrene (EPS) is one of the material innovations born of collaboration between ID lab and raw material producers. NEOPS® is manufactured using the Mass Balance method and is certified REDcert²*. This innovation, derived from renewable non-food resources, reduces the need to use fossil raw materials.

With NEOPS®, greenhouse gas (CO2) emissions are reduced by at least 30% (can be justified by internal calculations).

Products and technical parts made from NEOPS® can deliver a wide range of performances: thermal, fire resistance, shock absorption and even food contact.

1 Biomass from industrial waste unsuitable for food use or organic waste (organic waste from the forestry industry, not involved in deforestation, no competition with agricultural land for food production). Directive (EU) 2015/1513), Annex IX, Part A.

*Certification system for the use of sustainable biomass in the chemical industry. To date, 18 Knauf Industries sites are REDcert² certified: 16 in France and 2 in Spain.

This alternative to expanded polystyrene (EPS) is petroleum-free and certified by TÜV in accordance with REDcert². REDcert² certification guarantees that the producers of alternative raw materials have substituted the virgin fossil resource with a resource derived from the recycling of post-consumer plastic waste. Knauf Industries is also part of this REDcert² certification process for the manufacture and marketing of its CELOOPS® products.

At the end of their life, as NEOPS®, CELOOPS® products are sorted and recycled through existing EPS channels.

« A material of choice for packaging solutions and technical parts! »

Formulated on the basis of polypropylene (PP), this alternative complements Knauf Industries’ existing range of materials known as KAP’.

This material offers perfect welding quality in a protective atmosphere or under skin. It can be microwaved and pasteurised, and is 100% recyclable through existing PP channels. R’KAP® is available in Kapseal®, Kapclear® and Kaplight®.

Contact us for more information.

For several months now, Knauf Industries has been working hard to implement its new corporate vision and mission.

“We innovate to create lighter cars, safer food, better insulation and smarter industrial components. “. That’s our mission.

This vision and mission are our guiding principles. They reflect our determination to change our industrial processes and to develop products and services aimed at reducing our impact. This vision and mission have been defined with our employees, stakeholders and management on behalf of Knauf Industries as a whole.

At Knauf Industries we have been successfully offering modern solutions for furniture manufacturers. The two main materials that we apply in this sector are expanded polystyrene – EPS and expanded polypropylene – EPP. They are used both in indoor and outdoor furniture production offering numerous advantages for manufacturers and end-users.

What are polystyrene beads for the furniture industry?

Styrofoam granules are simply expanded polystyrene raw material in the form of small beads with a diameter of 2 to 8 mm, depending on the type. The polystyrene expansion process is carried out to a specific weight. Thanks to this, 1m3 holds up to 28 kg of polystyrene beads. The product is available in bulk form, packaged in accordance with client’s specification: in bags or bags and cartons.

Our offer includes Styrofoam beads of various diameters and dimensions that perfectly match the wide range of furniture and accessories. Our offer of expanded polystyrene beads is also addressed to manufacturers from the toy and textile industries. Our excellent quality products will work wherever resilient and solid polystyrene beads are needed.

At Knauf Industries we make high-quality polystyrene fillings for sofas, armchairs, pouffes, beanbags, mattresses, pillows and other types of furniture. Polystyrene beads are distinguished by their extraordinary functionality. As much as 98% of them consists of air, which means that the fillings made of them combine excellent protection with above-average lightness. This economical material is also a great insulator and excellent shock absorber. At the same time, it does not change its properties even under the influence of intensive exploitation.

For customers who are searching for a more sustainable variety of EPS beads we have developed NEOPS EPS beads. NEOPS is a certified expanded material from biomass resources (green waste) which constitutes a great alternative to the regular EPS. Thanks to its innovative manufacturing process the material’s CO2 emissions are reduced by at least 30%. Moreover, it is 100% recyclable in EPS channels (sorting bins, waste sorting centers, collection points) and KNAUF Circular® – our own EPS collection program. The appearance and technical characteristics of NEOPS are like expanded PS foam performances (EPS). The product and process are certified REDcert² by the TÜV.

The expanded polystyrene granules offered by Knauf Industries come in various sizes, which allows for their wide application. The products are completely safe and user-friendly. They do not contain any impurities or toxic and harmful substances.

Due to their small size and excellent plasticity, polystyrene beads reach hard-to-reach nooks and crannies, filling them perfectly. Thanks to this, you can be sure that each piece of furniture, even the most intricate forms, will keep its perfectly profiled shape. Another advantage of the expanded polystyrene filler is its very low weight. Thanks to this, all furniture filled with beads can be easily moved to any place, which increases their usability and pleasure of use.

The beads are very easy and convenient to use. They are distinguished by perfect elasticity, and their subtle shifting under the influence of the weight of a person sitting on a pouffe or sofa adds to the furniture features of extraordinary comfort.

The big advantage of the beads is also their durability and solidity. This makes the granulate retain its properties, volume, and shape for many years, which translates into long-term functionality and comfort of using furniture.

In addition to excellent functional properties, furniture pieces with polystyrene filling are also characterized by a very aesthetic appearance. They are perfectly filled, which affects their effective design. They also guarantee extraordinary pleasure and comfort of rest or sleep.

An excellent example of products that use polystyrene filling on a large scale are pouffes and beanbags. These are popular seats in the form of bags filled with small beads, whose characteristic design guarantees comfortable rest and deep relaxation. Beanbags perfectly adapt to the shape of the body. Importantly, you can freely change their form, without fear that the seat will be destroyed, or its current shape will remain that way forever. The secret of the comfort and high functionality of this piece of furniture lies precisely in the use of the proper polystyrene filling in the form of granules. Usually, furniture from manufacturers with whom we cooperate is filled with Knauf expanded polystyrene granulate on the production line, but nothing stands in the way of doing it yourself. For this reason, our granules are perfect for filling handmade furniture, e.g. pouffes, bean chairs, sofas or armchairs that are personalized or made to order.

Owing to the cushioning properties of EPS the beads from this material are also chosen by manufacturers of products for kids like floor pillows and cushions.

Headboards are another growing application of EPS beads is the furniture industry. The beads fill out the cushion of the headboard making it the perfect protection for bed user’s head. Moreover, they offer numerous design possibilities to personalize the headboards and make them a unique and distinctive furniture peace. The manufacturing process is controlled: our products are double-covered.

We carry out deliveries of wholesale quantities, mainly full-truck loads. The offered granules are carefully packed in safe packaging. We guarantee favorable, competitive prices as well as professional advice and assistance in choosing the right solution for furniture manufacturers.

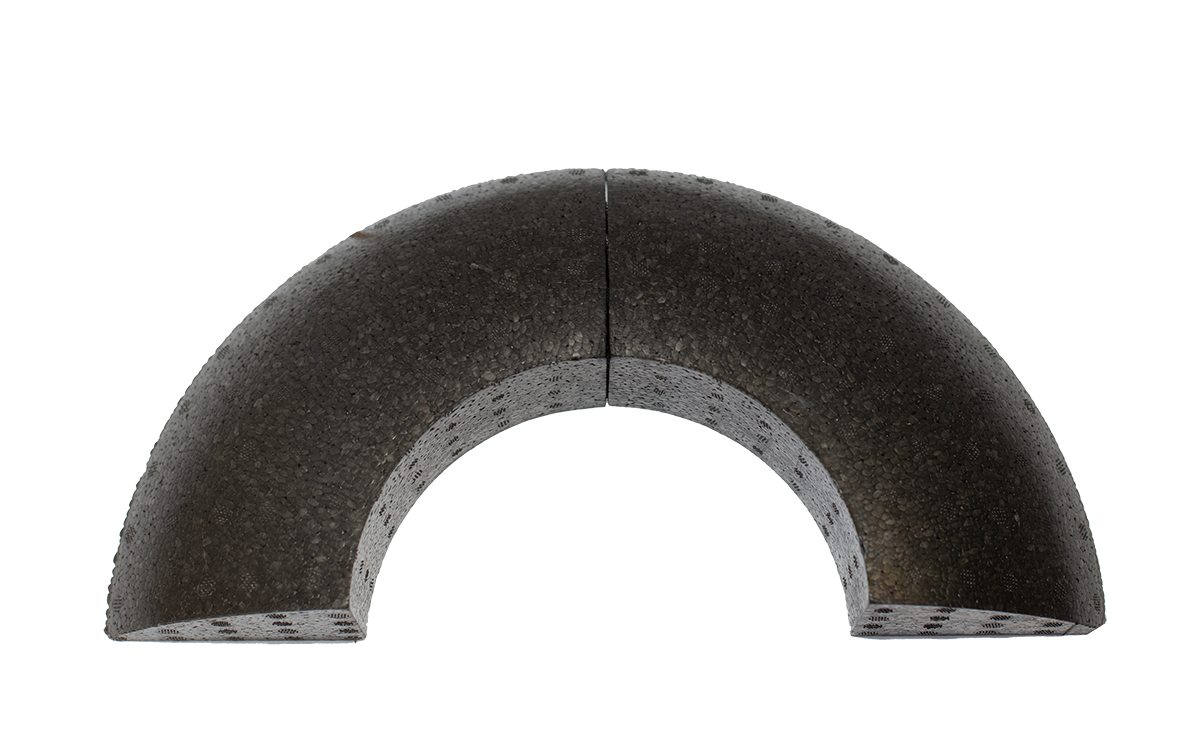

While expanded polystyrene (EPS) is a well-known material in the furniture industry, expanded polypropylene (EPP) is an innovative solution that is gaining more and more popularity in furniture component manufacturing. This light-weight and at the same time extremely durable foam material began to be used as a structural element in the construction of furniture. Furniture manufacturers choose polypropylene foam as an alternative to wood, plywood and in some case event to metal components. The material is successfully applied in both: indoor and outdoor as well as garden furniture production.

The parts from expanded polypropylene can easily constitute structural parts of sofas, armchairs, seats, and other furniture. The material is made up of 95% air hence EPP parts for furniture are 10 times lighter than wood and 40 times lighter than the ones made of aluminum. This means that furniture made using this material does not weigh much and is ergonomic which is crucial for end-users. One more important property of the material which is valued by the industry is the so-called “shape memory” meaning that EPP comes back to its original shape after the stress applied to it ceases. Thanks to that the furniture with EPP parts is comfortable and durable at the same time.

Expanded polypropylene allows for extraordinary freedom in designing forms and shapes that are unattainable in metal bending or in wood processing technologies. In particular all rounded shapes that give the furniture pieces a unique look are easily attained with the foam molding technology used for EPP component manufacturing. That is one of the reasons why innovative producers from the industry incorporate expanded polypropylene in their solutions for furniture. At Knauf Industries, we work closely with the design departments of furniture companies to support them in the replacement of traditional technologies with EPP. We design and manufacture reliable components for manufacturers of upholstered furniture who want to streamline their production process.

Furniture components made from EPP offer many advantages from the production process point of view. The EPP molding process applied in the part production at Knauf facilities guarantees the part accuracy and repeated quality which has an outstanding advantage over wood processing technology. The lightweight EPP parts can be easily assembled during the furniture production process. Moreover, one part can be designed to fit many various models based on the modularity concept which facilitates logistics and management of components in the client’s warehouse. Molding of components helps to reduce the number of operations in the assembly process. They also can be easily attached to one another either with help of regular screws or without them, if designed so. On the top of it, EPP foam can be used to create complex components with overmolded plastic or metal inserts.

The use of EPP not only does simplify the assembly process but also makes it more environment friendly. Polypropylene foam is a mono-material which is 100% recyclable as it is composed only of polypropylene granules filled with air. What’s more, there are varieties manufactured with recycled polypropylene, the so-called rEPP which offers an even more sustainable alternative to other traditional materials applied in the furniture industry. With rEPP our clients can decrease their CO2 footprint which constitutes a relevant part of their CSR strategies.

At Knauf Industries we support our clients all the way through the solution implementation. Our designers and product engineers can participate in the design of the customized EPP parts. In the beginning of each project, we carry out a feasibility study to define the most optimal solution from the process point of view. In addition to the component production process, we coordinate the development of the tooling necessary for foam molding of the parts. Therefore, the implementation of the innovative EPP solutions into our client’s production processes runs smoothly.

The plastics industry is getting organised with the setting up of a French recycling scheme for EPS and XPS packaging ♻👍

In France, some household, industrial and commercial packaging is made of EPS and XPS resins, used for their impact protection and isothermal properties.

Expanded styrenic packaging is composed of 95% air, which makes it an advantage in terms of low CO2 emissions (amount of material used, transport, etc.) and optimisation of the amount of material used.

“10 industries and organisations have given birth to this project called CREASTYR”.

The industrial signatories of this roadmap are now pooling their expertise to :

👉 Develop the collection and sorting of EPS and XPS by increasing the collection from professionals (industry and distribution) and private individuals (in waste collection centres and waste from selective sorting) to ensure the material recovery of 100% of this waste and thus avoid its burial or incineration.

👉 Increase recycling and ensure the sustainability of the future sector by aiming to recycle 100% of EPS and XPS packaging collected in France by 2025 and reincorporate the recycled material into new products to make the sector technically and economically viable.

👉 Measure, raise awareness and communicate to make the existence of the collection and recycling channel known and thus enable the holders of the deposit to carry out the appropriate sorting gesture and also share figures on the deposit, collection and recycling.

Knauf Industries is committed to promoting, supporting the implementation of and achieving the objectives of the roadmap for the establishment of a polystyrene recycling network in France.

This initiative aims to develop our Knauf Circular expanded polystyrene waste collection and recycling service, already in place since 2020 and intended for our customers and partners.

Read the press release and the CREASTYR roadmap for more details on the initiative.

The information was published on LinkedIn and on the internet ➡ Crea-STYR Elipso

EcoVadis is a start-up that offers companies an evaluation and rating tool (from 0 to 100) of the CSR of their suppliers according to criteria based on the 17 sustainable development objectives set by the UN.

As an industrial manufacturer of packaging and technical parts, Knauf Industries is aware of all global changes that can impact its business. In response to customer demand, Knauf Industries joined the EcoVadis extra-financial rating platform in 2018, with the aim of becoming a supplier of choice by improving its CSR practices.

📢 Read our second Corporate Social Responsibility report!

This year again, our efforts paid off as our score improved by 5 points, with a score of 64 / 100, we retain the silver🥈 medal. This result puts us in the top 25% of companies assessed by EcoVadis.

EcoVadis has become a strategic tool for us and a way to structure what we do.

As part of our CSR policy, we have set ourselves a target of achieving gold status by 2025.

Knauf Industries announces new company vision and mission, to set the tone for the future.

We are delighted to introduce our new company vision and mission:

This vision and mission pave the way into the future for Knauf Industries. It describes our ambition and what we want to achieve with our products, for our stakeholders, for our customers and for the environment we live in. This vision and mission have been created in collaboration with our employees, our stakeholders and our management, speaking for all of Knauf Industries. This movie explains you more about our aspiration of reducing the weight on our planet: