retour

We support our customers and partners in their circular economy approach.

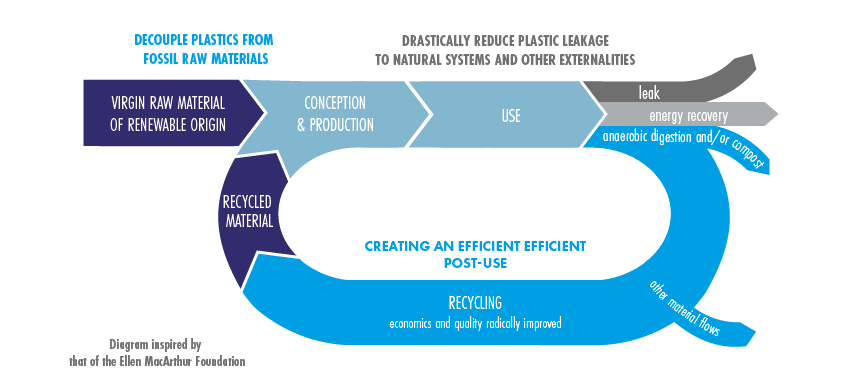

Knauf Industries is prioritising its transformation towards the circular economy by innovating in three areas: materials from renewable resources, eco-design and end-of-life. Our solutions fit perfectly into the circular economy scheme proposed by the Ellen MacArthur Foundation.

At Knauf Industries, we select materials with the lowest environmental impact for the required quality of use and technical performance. We optimise the design of our packaging and the quantity of material used.

Our role is to create solutions for you that save material while preserving the quality of your products. We favour single-material solutions and select our raw materials according to their technical characteristics.

It is essential for us to offer reliable products and solutions, designed and manufactured to leave a minimal environmental impact throughout the life cycle!

Knauf Industries also innovates on the production process to reduce energy consumption and CO2 emissions.

To achieve this, we are equipping our factories with sensors to measure energy and fluid consumption, optimising the process by recovering energy and developing closed loop processes to reduce consumption.

Finally, the implementation of environmental performance measurement tools allows us to monitor the CO2 impact of our sites and products.

ID lab offers its customers innovation workshops to evaluate solutions that have less impact on the environment.

Our products are designed with recyclable materials according to our good design practice guidelines in order to meet customer requirements with the strict minimum of material needed, but also the requirement of product recyclability at the end of its life. These good design practices are regularly updated with feedback from our developments.

Our knowledge of material performance also enables us to offer you reusable solutions, thus reducing material consumption. We offer creative workshops to study the evolution of single-use solutions towards multi-use solutions.

We continuously invest in eco-responsible production methods!

Our ID lab innovation and development centre develops material solutions that originate from a renewable resource and avoid the use of fossil resources.

Three areas of research are prioritised: materials incorporating up to 100% recycled material, materials derived from biomass and biosourced/biodegradable materials.

Knauf Industries ensures that the solutions developed have sufficient resources to serve our customers, but also that these resources do not compete with food resources (use of organic waste). Any material solution must have an existing recycling channel or one that is being set up in the short term so that the solution from a renewable resource remains a circular solution.

After use, our solutions become waste that must be collected to give it a new life as raw material for a new product in an open or closed loop.

Knauf Industries has been a committed recycler for many years, and continues to work to increase the amount of recyclable material actually recycled and to reduce material leakage.

Knauf Industries is the first EPS converter to offer a collection service to ensure the reuse of EPS waste through its Knauf Circular service.

ID lab is innovating to guarantee a second life for its waste. Several lines of work are developed either in a closed loop with the reintegration of qualified and treated waste in some of our products or by transformation of the waste in order to be integrated into the raw material, or in an open loop with physical or chemical transformation to obtain raw material from waste but with properties equivalent to those of the virgin material.

We are at your disposal to bring you the best possible solutions.